Domestically, the thriving construction industry will lead to an increase in demand for timber products. In Australia, the demand for softwood products is predicted to triple by 2050. This means that over the medium to long term, cultivating more plantation trees will be absolutely crucial to our future wood supply needs in Australia.

Australian Panels has long recognised that the continued development of plantations is necessary to support the softwood processing sector. Together with Plantation Pine Products, Australian Panels endorses the importance of farm forestry to secure additional wood resources and continue to cultivate tomorrow’s forests while ensuring the sustainability of its operations.

Plantation Pine Products has recently planted 2.6 million trees across four sites on 1,900 hectares of converted farmland in a 10-week timeframe. Starting in mid-June and planting at an average rate of 26,000 trees a week, the project progressed at a rapid pace. Considering that all 2.6 million trees were planted by hand, the 50 dedicated workers responsible made incredible time.

The seedlings were propagated in October 2022 and took 9 months to grow into saplings ready for a more permanent establishment. On a short rotation once the trees have reached maturity they could be harvested in as little as 14 years. Alternatively, they may be left for 25 – 30 years to be harvested on a longer rotation for a higher timber yield. After being harvested, they’ll be carted to Oberon by Plantation Pine Products’ fleet of heavy vehicles to be debarked and chipped. From there, they’ll be processed by Australian Panels to be manufactured into a range of MDF and particleboard products.

Plantation Pine Products also currently manages a number of plantation forests as well as independently and jointly investing in greenfield, established and mid-rotation forests. Maximising the use and value of resources brings major economic, social and environmental benefits. It contributes to innovation, growth, and job creation while reducing our impact on the environment through the collection of carbon in wood.

The conversion of grazing land to forests is often part of afforestation and reforestation efforts. Plantation Pine Products offers plantation management services for the preparation, establishment, and ongoing afforestation services such as silviculture, fire protection and forest maintenance.

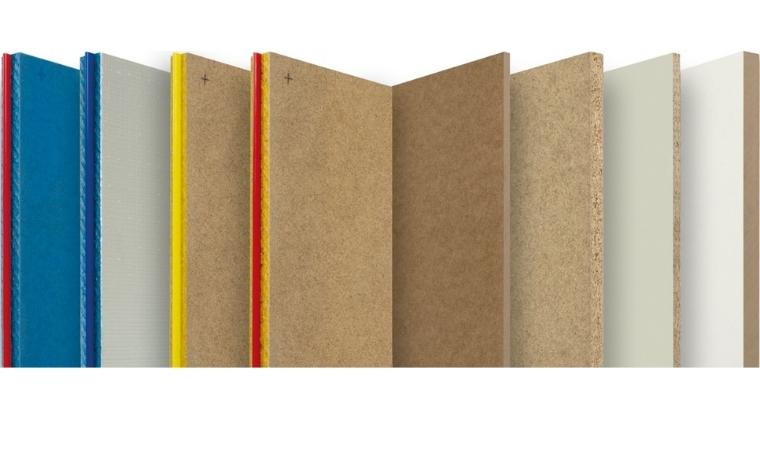

At Australian Panels we are extremely proud to be a part of this positive impact. The quality of our products and our impact on the environment is at the forefront of our business model. Our wide range of MDF and Particleboard products – STRUCTAflor, STRUCTApanel, CUSTOMwood, CUSTOMpine, COLOURpyne and ULTRApine – are all made with timber grown and harvested from managed, renewable plantation pine.

The town of Oberon has a long and close association with the timber industry and is a vital link to the history of Australian Panels and the STRUCTAflor range of products.

In 1929 The Forestry Commission of NSW recognised the suitability of the Oberon district for the growing of softwoods, and the first pines were planted. The Forestry Commission put out a tender to purchase the thinning’s from the plantation pine forest which subsequently led to the building of the first particleboard mill in Oberon in 1961.

The first particleboard flooring material produced out of the Oberon mill was in 1973. After further improvements and advances in resin technology, shortly after the iconic YELLOWtongue particleboard was born. Over time, variations of the particleboard product range began to diversify and develop under the STRUCTAflor brand to cater to a wider spectrum of construction needs. This dedication to excellence laid the foundation for its future success.

In 2018 Australian Panels commissioned Australia’s newest particle board line at the Oberon facility. With the most advanced machinery and technology, the Oberon particleboard line is the youngest and most efficient in the Southern Hemisphere.

The Oberon facility also boasts Australia’s largest rooftop solar system. The 10 MW rooftop solar system comprises over 27,000 solar panels which covers an area of 8 football fields and generates 14 GWh of clean energy annually, helping to reduce carbon emissions by up to 15,000 tonnes.

The company has continually invested in state-of-the-art manufacturing processes, ensuring precision and consistency in its products. And just as they were the first product of their kind on the market, 50 years later they continue to lead the way in innovation and development of engineered panel solutions.

In the building business, your reputation is only as good as the materials you use. That is why when it comes to structural particleboard flooring, you need a product you can trust and a partner you can rely on to keep pace with ever-changing lifestyle and construction requirements. After years of dedicated production and innovation, YELLOWtongue and the STRUCTAflor range remain the number one choice for Australian builders.

As STRUCTAflor celebrates its first half-century, it is poised for an even brighter future. With a continued focus on innovation, sustainability, and quality, the brand is well-positioned to meet the evolving needs of the construction industry with the recent investments into plantation pine.

STRUCTAflor’s journey over years is a testament to its resilience, and unwavering commitment to investment and product innovation. As we look ahead to the next 50 years, this iconic Australian brand will undoubtedly continue to shape the construction landscape, leaving a legacy of sustainable, high-quality building materials for generations to come.

Click here for more information on Plantation Pine Products, or here to learn about Australian Panel's commitment to manufacturing a sustainable future.